Warp Drive

Have you ever wondered what a warp propulsion system actally looks like? Well here is your chance to find out, welcome to the tour through warp propulsion systems. Here you will learn everything that goes on in a standard warp core system. During the tour various images are displayed, to reduce the page load-time these images have been reduced in size. If you would like to examine the pictures a little more closely, save them to disk and enlarge them.

All of the images in this article were found on the web but their creators are unknown.

This article was provided by Colin McHendry.

Matter/antimatter reaction assembly (M/ARA)

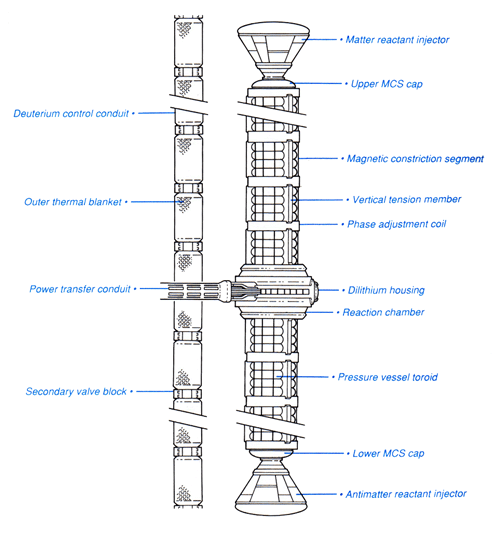

As the warp propulsion system is the heart of the starship, the M/ARA is the heart of the warp propulsion system. The M/ARA is variously called the warp reactor, warp engine core, or main engine core. Energy produced within the core is shared between its propulsion and the raw power requirements of major ship functions. The M/ARA consist of four subsystems:

- reactant injectors

- magnetic constriction segments

- matter/antimatter reaction chamber

- power transfer conduits

Reactant injectors

The reactant injectors prepare and feed precisely controlled streams of matter and antimatter into the core. The matter reactant injector(MRI) accepts supercold deuterium from the primary deuterium tankage (PDT) and partially preburns it in a continuous gas-fusion process. It then drives the resulting gases through a series of throttleable nozzles into the upper magnetic constriction segment. The MRI consists of a conical structural vessel 5.2 x 6.3 meters, constructed of dispersion-strengthened woznium carbmolydenide.

Twenty-five shock attenuation cylinders connect it to the PDT and the major spacecraft framing members, maintaining 98% thermal isolation from the remainder of the Battle Section. In effect, the entire WPS "floats" within the hull in order to withstand 3x theoretical operational stresses. Within the MRI are six redundant cross-fed sets of injectors, each injector consisting of twin deuterium inlet manifolds, fuel conditioners, fusion preburner, magnetic quench block, transfer duct/gas combiner, nozzle head, and related control hardware. Slush deuterium enters the inlet manifolds at controlled flow rates and passes to the conditioners, where the heat is removed to bring the slush to just above the solid transition point. Micropellets are formed, preburned by magnetic pinch fusion, and sent down into the gas combiner, where the ionized gas products are now at 106K. The nozzle heads then focus, propel and align the gas streams into the constriction segments. Should any of the nozzels fail, the combiner would continue to supply the remaining nozzles, which would dilate to accommodate the increased supply. Each nozzle measures 102 x 175 cm and is constructed of frumium copper yttrium 2343.

Magnetic constriction segments

The upper and lower magnetic constriction segments (MCS) constitute the central mass of the core. These components work to structurally support the matter/antimatter reaction chamber, provide a pressure vessel to maintain the proper core operating environment, and align the incoming matter and antimatter streams for combining within the matter/antimatter reaction chamber (M/ARC). The upper MCS measures 18 meters in length, the lower unit 12 meters. Both are 2.5 meters in diameter. A typical segment comprises eight sets of tension frame members, a turoidal pressure vessel wall, twelve sets of magnetic constrictor coils, and related power feed and control hardware.

The constrictor coils are high-density, forced-matrix cobalt-lanthanide-boronite, with thirty-six active elements configured to provide maximum field strength only within the pressure vessel and permitting little or no field spillage into main engineering. The pressure vessel toroids are alternating layers of vapor-deposited carbonitic ferracite and transparent aluminum borosilicate. The vertical tension members are machined tritanium and cortenite reinforcing whiskers, and are phase transition-bonded in place as the vehicle frame is being assembled to produce a single unified structure. All engine frame members possess integral conduits for structural integrity field energy reinforcing under normal operation. The outermost transparent layer serves as one observable gauge of engine performance, as harmless secondary photons are emitted from the inner layers, providing a visible blue glow. The peristaltic action and energy level of the constrictor couls can be readily seen by the CEO. As the streams of matter and antimatter are released from their respective nozzels, the constrictors couls compress each stream in the Y axis and add between 200 and 300 m/sec velocity. This insures proper alignment and collision energy for them each to land on target within the M/ARC at the exact center of the chamber. It is at this spot that the M/A reaction is mediated by the dilithium crystal articulation frame.

Matter/Antimatter reaction chamber

The (M/ARC) consists of two matched bell-shaped cavities which contain and redirect the primary reaction. The chamber measures 2.3 by 2.5 meters in diameter. it is constructed from twelve layers of hafnium 6 excelion-infused crabonitrium, phase-transition welded under a pressure of 31,000 kilopascals. The three outer layers are armored with acros-senite arkenide for 10x overpressure protection, as are all interface joints to other pressure bearing and energy-carrying parts of the system.

The equatorial band of the chamber contains the housing for the dilithium crystals articulation frame (DCAF). A hatch allows access to the DCAF for replacements and adjustments. The DCAF consists of an EM-isolated cradle to hold approximately 1200 cm2 of crystal, plus two redundant sets of three-axis crystal orientation linkages. The crystal must be manipulated with six degrees of freedom to achieve the proper angles and depths for reaction mediation. Connecting the equatorial band to the upper and lower halves of the chamber are twenty-four structural pins. These pins are hafnium 8 molyferrenite and are reinforced in tension, compression, and torsion, and are continuos with the engine structural integrity field. Running along the center of the equatorial band are two layers of diffused transparent tritanium borocarbonate for reaction energy visual monitoring.

Dilithium Crystal Reaction

The key element in the efficient use of M/A reactions is the dilithium crystal. This is the only material know to federation science to be nonreactive with antimatter when subjected to a high frequency electromagnetic (EM) field in the megawatt range, rendering it "porous" to antihydrogen. Dilithium permits the antihydrogen to pass directly through its crystalline structure without actually touching it, owing to the field dynamo effect created in the added iron atoms.

The longer form of the crystal name is the forced-matrix formula 2<5>6 dilithium 2<:>1 diallosilicate 1:9:1 heptoferranide. This highly complex atomic structure is based on simpler forms discovered in naturally occurring geological layers of certain planetary systems. It was for many years deemed irreproducible by known or predicted vapor-deposition methods, until breakthroughs in nuclear epitaxy and antieutectics allowed the formation of pure, synthesized dilithium for starship and conventional powerplant use, through theta matrix composting techniques utilizing gamma radiation bombardment.

Dilithium

Crystalline substance used in warp propulsion systems aboard starships. Dilithium regulates the matter/antimatter reactions that provide the energy necessary to warp space and travel faster than light. Naturally occurring dilithium is extremely rare and is mined on only a few planets. Until the advent of recrystallization techniques that permitted the production of synthetic dylithium, the crystals were among the most valuable substances in the galaxy. This breakthrough occurred in 2286 when Spock devised a means whereby dilithium crystals could be recrystallized by exposure to gamma radiation (high energy photons) that were re-products of nuclear fission reactions. In later years, theta matrix compositing techniques permitted even more efficient recrystallization. By the late 2360s, recrystallization techniques had advanced to the point that crystals could be recomposited while still inside the articulation frame of the dilithium chamber, extending the useful life of the crystals even further.

| Academy Library |

|---|

|