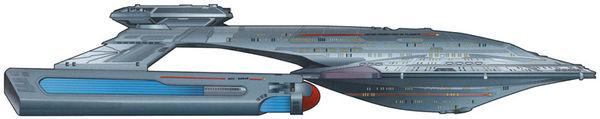

Akira class/Design Notes

| Utopia Planitia Fleet Yards |

|---|

|

CRUISERS

Computer DevelopmentThe updated Computer cores found on the Akira-class are newer versions of the Galaxy Class Isolinear Processing cores. The system is powered by a smaller, regulated EPS conduit directly from the warp core. Cooling of the isolinear loop is accomplished by a regenerative liquid nitrogen loop, which has been refit to allow a delayed-venting heat storage unit for "Silent Running." For missions, requirements on the computer core rarely exceed 45-50% of total core processing and storage capacity. The rest of the core is utilized for various scientific, tactical, or intelligence gathering missions - or to backup data in the event of a damaged core. Each core incorporates miniature subspace generators, which creates a symmetrical, nonpropulsive, field distortion of 3350 millicochranes within the faster-than-light (FTL) core elements. This permits data to be processed and passed at rates far exceeding the speed of light. Number of computer coresTwo; The primary core one occupies space on decks 7, 8 and 9 far astern. The secondary, emergency core is much smaller than the first and is located adjacent to Enviromental Control on Deck 16. The Core elements are based on FTL nanoprocessor units arranged into optical transtator clusters of 1,024 segments. In turn, each cluster is grouped into processing modules composed of 256 clusters controlled by a bank of sixteen isolinear chips. Each core comprises seven primary and three upper levels, each level containing an average of four modules. SubprocessorsA network of 200 quaditronic optical subprocessors is distributed throughout the ship, augmenting the main cores. Within the habitable volume of the ship, most of these subprocessors are located near main corridor junctions for easy service and updating. While these subprocessors do not employ faster-than-light elements, the distributed processing networks improves over all system response and provides redundancy in emergency situations. Both the Bridge and the Tactical Information Center have 30 dedicated subprocessors, allowing for the operation of ship’s systems and flight operations in the event of computer core failure. These subprocessors are linked to the main computer cores through several redundant, protected optical data network trunks, as well as through ultra-high frequency radio (RF) links, providing even emergency data communications with the bridge. Core MemoryMain memory storage for the primary computer core is provided by 2,048 dedicated modules of 144 isolinear optical storage chips. Under LCARS software control, these modules provide access to memory averaging around 4600 kiloquads/second. Total storage capacity of each module is about 630,000 kiloquads, depending on the current LCARS software configuration. Hull Developmenthe primary spaceframe of the Akira-class is created from an interlocking series of tritanium/duranium alloy macrofilament truss frames. These members average 1.25 square meters in cross section and are located, on average of every 25 meters across the ship’s exterior. These larger trusses provide the skeletal framework for the vast majority of major ship systems, such as the primary and secondary impulse engines, the warp nacelle mounts, the docking latch interfaces, and along the centerline of the hull structure. Smaller trusses, about half the size of the standard structural truss, are located approximately every five meters, and provide internal and core support for the spaceframe interior. Attached through these networks of trusses are a variety of mechanisms which utilize the hull for its operation, including portions of the Deflector Shield System, as well as the Subspace Radio antenna system.

SECONDARY HULL FRAMEWORKMounted to the primary spaceframe is a secondary framework of microextruded terminium trusses to which the inner hull structure is physically attached. This frame work is mounted by a series of semirigid polyduranide support rods, permitting a limited but significant amount of stress relief during superluminal maneuvers as well as sound and vibration isolation. Secondary segments are separated from each other, though still connected mechanically to the primary spaceframe, to allow for replacement of inner hull compartments and segments without compromising the primary spaceframe structural integrity and making replacement at deep space repair facilities easier and less time intensive. The Structural Integrity Field (SIF) is active during powered spaceflight (Impulse and Warp powered flight), providing a series of layered force fields which reinforce the physical framework. The SIF is distributed through a network of molybdenum-jacketed waveguides, which in turn distribute the SIF energy into ceramic-polymer conductive elements throughout the spaceframe. Without the SIF, the spaceframe would be unable to withstand accelerations greater than 7.4 m/sec^2 without significant hull deformation, or greater than 19.5 m/sec^2 without unrecoverable structural damage. This means that, without the SIF active, the hull would begin to collapse under its own weight within the confines of a gravity well (see section 2.4) The exterior hull is joined to the primary load-bearing trusses by means of a series 4cm diameter electron-bonded duranium pins at 1.25 meter intervals. These pins are slip fitted into an insulating AGP ceramic fabric jacket that provides thermal and radioactive insulation between the spaceframe and the exterior hull. The pins, jacketing and hull segments are then gamma welded together. Hull LayersThe exterior shell of the spacecraft consists of multiple layers which afford both structural and atmospheric integrity for the spaceframe, integral waveguides and field conductive members for the structural integrity field (SIF), as well as pathways for other utilities (including navigational and defensive deflector grids) and necessary resistance to radiation and thermal energy. The exterior shell substrate is composed of interlaced microfoam duranium filaments. These filaments are gamma welded into a series of contiguous composite segments that are 5 cm. thick and are, on average, two meters wide. The substrate segments are electron bonded to three reinforcing layers of 1.2cm biaxially stressed tritanium fabric, which provides additional torsion strength. In addition to the standard duranium hull plates, Starfleet Generation II Ablative Armor has been installed over the entirety of the hull. See below for more details Armor DevelopmentThe ablative armor system was developed by Starfleet R&D, Tokyo, and the various factors that delayed the deployment onto frontline vessels has been solved. This armor is the second generation of deployed by Starfleet. The armor is still 2cm thick, providing a honeycomb strata of destructible material that reacts violently when exposed to high-end, directed phased energy beams such as phasers, disrupters or polaron beams. The armor melts away in a endothermic reaction, creating a cloud of diffuse molten metal that scatters the coherence of the incoming beam, further enhanced over the Generation I material by the inclusion of gamma-developed Thorium, known for its phased energy reflection properties. The Akira class starship has the Ablative Armor placed around the bridge, nacelle mounts, and aft-sail torpedo mount. The armor works in two stages; in the event of a shield disruption, phaser or energy EM is first dissipated over the hull armor surface, when the classified threshold is achieved, the molecular matrix bakes off, causing it to boil at a controlled rate. The boiling off carries away a large fraction of the energy directed at the vessel, with the rest deflected by the resulting cloud of armor shards. In most cases, the boil-off cloud continues to disperse the incoming beam, negating the higher damage harmonics Weapons DevelopmentThe Akira class starship contained several experimental technologies that would later be rolled out to the fleet and the prequel of later technology. One such technology is a more automated high-speed launcher. The first-generation version of this was found on the New Orleans class and Saber class, before being rolled out to the Excelsior class starships as refit cycles allowed. The Akira-class boasted the second generation of these technologies, which allowed up to 5 tubes per launcher and 15 torpedoes in a single salvo. This would be the basis of the third-generation launcher deployed on the Sovereign class and Norway Class starships. This launcher deployed Mark XXV photon torpedos, but could be configured for either photon or quantum torpedoes.

|

- Black-and-white ship illustrations by Tim Davies unless otherwise noted. Used with permission. All other images are copyright to their respective owners.

- Black-and-white ship illustrations by Tim Davies unless otherwise noted. Used with permission. All other images are copyright to their respective owners.

| REV SD 239705.25 |

|---|